Introduction to the individual parts of the paper impregnation line

The standard paper impregnation line consists of the following main components.un-winder, first impregnating station, secondary coating machine, dryer, cooler, web aligner, tractor, paper cutter, stacking system.

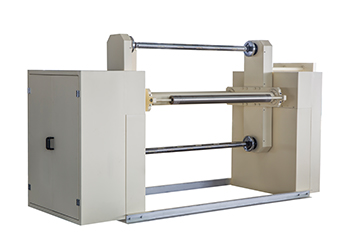

Unwinder

Unwinder with air-swelling shafts(or non-shaft) to continuously unwind and produce, and keep the correct paper tension constant through the automatic regulating mechanism.

Automatic splicer

Automatically paper splicing from the top. Stick the new paper web to the old paper if the roll is changed and cut off the old paper. Two edge cutting devices for the edge trimming, can save resin.

First impregnating station

It consists of a frame, S-roller, backing rollers, metering rollers, glue basin, etc. The paper is pre-impregnated and the glue pick-up is controlled by adjusting the gap between the metering rollers.

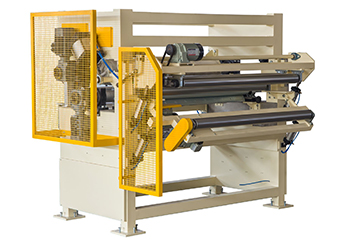

Secondary coating machine

Newly designed frame for more stable operation. The smoothing roller frame can be raised in its entirety to facilitate the cleaning of the anilox rollers. Two times resin covering onto both sides of the paper according to process requirements.

Dryer

Air flotation type dryer, drying the paper after first impregnator and secondary coator. The heating medium can choose to use thermal oil or natural gas. Special frame construction and insulation for energy savings.

Cooler

Attached to the back of the dryer to cool the paper. Lengths can be customized on request and equipped with a cooling device.

Web aligner

Enable accurate and reliable web tension control and aligning of the web come from dryers.

Tractor

Pull the web through the machine and cool the paper for further processing so as to maintain paper tension.

Rotary cutter

Precise sheet cutting by means of START-STOP function and spin-type knife design to ensure optimized wear combined with excellent cutting quality.

Stacking system

Consists of a belt and lifting table for the stacking of finished paper. A double-layer automatic stacking system can be used as an option depending on the requirements of the production process.

How can we support your business

1. Complete impregnation line

2. Single units( unwinder, impregnating station, dryer, coating machine, coole, web aligner, cutter, conveyor, lifting table)

3. Resin making equipment and resin mixing system

4. Heat recovery system and air treatment

5. Spare parts

6. Laboratory equipment( test press machine, manual impregnation device, test device, and etc)

7. Technology transfer(resin formulations, impregnation technology, plant planning)